For more details about these assumptions, read our post, the problem with the economic order units of production method quantity model. If actual units are not available, then you can use expected sales figure based on your sales trend. DTC brands that sell with Cogsy generate 40% more revenue on average and save 20+ hours weekly on inventory management. However, optimal quantities generally do not agree with bulk volumes, so you’ll need to brace yourself for higher unit costs if you’re using EOQ. EOQ assumes that none of your products were sold to you at a discounted rate.

Flowspace’s platform also leverages historical sales data and other factors to help forecast future product needs and breakeven point bep definition create a customized EOQ calculation. This means brands can avoid overstocking, saving them money on unnecessary inventory costs. Whether your brand is just starting out or already a large enterprise, Flowspace’s platform is designed to scale according to your business needs. Inventory management software with EOQ functionalities can optimize inventory levels, reduce costs, and improve order accuracy.

- To address this, businesses may incorporate forecasting techniques specific to seasonal trends and employ safety stock strategies.

- Maintaining optimal inventory levels frees up working capital for other investments and improves cash flow.

- The EOQ model implicitly assumes a trade-off between inventory holding and setup costs.

- Plus, the platform sends alerts when inventory levels are low, empowering brands to reorder products before they run out.

- The cost of inadequate carrying, on the other hand, is also an important consideration for the calculation of order quantity.

- Sometimes it makes sense for a retailer to buy a product in bulk from the vendor to get a discount.

What makes the EOQ a compelling tool is that it is dynamic and can be revisited from time to time as your business grows. If there’s a change in any of your inventory costs, you can always tweak the formula and generate a new EOQ to suit the current conditions. A next-gen inventory software can help you calculate this economic order quantity automatically, helping you make informed business decisions. Many inventory management software solutions come with built-in EOQ calculation features. These tools help businesses streamline inventory replenishment processes, optimize inventory levels, and reduce overall inventory costs.

You’re vulnerable to stockouts when things go off-plan, hurting your profits and customer satisfaction. That’s why EOQ is rarely used alone; it must be part of a full inventory control strategy. The EOQ formula assumes stable costs across transportation and storage. In practice, you can have fixed costs in a warehouse (rent, depreciation of machines) but also variable costs like workforce or electricity. For this item, we end up placing an order every 2 months, compared to every 18 days in the first example.This contrast highlights how demand and holding costs influence order frequency. Economic order quantity is important because it helps companies manage their inventory efficiently.

What happens to EOQ when order quantity increases?

Using the EOQ for inventory planning can help you meet demand while maintaining a reasonable inventory balance. While at first glance over-ordering may seem like a safer move, you may be tying up too much of your cash in physical stock during periods of low demand. When inventory falls to a certain level, the EOQ formula, if applied to business processes, triggers the need to place an order for more units. It’s not just about math equations; it’s about unlocking the potential for significant cost savings and optimal inventory management.

- According to the economies of scale, the larger quantities of orders result in decreased per-unit cost of ordering.

- One most popular and common methods of calculating the quantity to be ordered are Economic Order Quantity (EOQ).

- In the absence of this technique, the companies might end up sticking too much cash into large amounts of inventories.

- Similarly, if a company wants to cut its ordering costs, it must reduce the number of orders placed which is possible only when order size is large.

- If there’s a change in any of your inventory costs, you can always tweak the formula and generate a new EOQ to suit the current conditions.

Safety Stock Assessment

Calculating EOQ for each item in stock will help you determine the right amount that meets demand, with fewer products in your store. This is important, as holding inventory on-site results in additional real estate costs, security fees, utility bills, insurance premiums, and other related costs. Its cost per order is $400 and its carrying cost per unit per annum is $10.

The goal is to find the order quantity that minimizes the sum of these costs, and it often involves finding a balance between the two. By leveraging these technologies, businesses gain valuable insights into demand patterns, order histories, and other relevant metrics. This data-driven approach facilitates more accurate EOQ calculations and adjustments.

In that case, adding simple inventory principles can be a game-changer. We assumed supply lead time is stable when calculating order frequency based on the EOQ. Seasonal delays, supply chain disruptions, and holiday slowdowns can all throw off timing. Malakooti (2013)10 has introduced the multi-criteria EOQ models where the criteria could be minimizing the total cost, Order quantity (inventory), and Shortages. FreshBooks expense-tracking software solutions help businesses organize their receipts and spending and automatically track and categorize inventory expenses. This gives company owners the data they need to analyze their spending and profits, with no manual entry required.

When you use the economic order quantity model can help you cut down on dead stock and obsolete or expired products. By calculating the optimal order quantity of each item, you will be more likely to sell it well before its best-by date. The calculation also assumes that both ordering and holding costs remain constant.

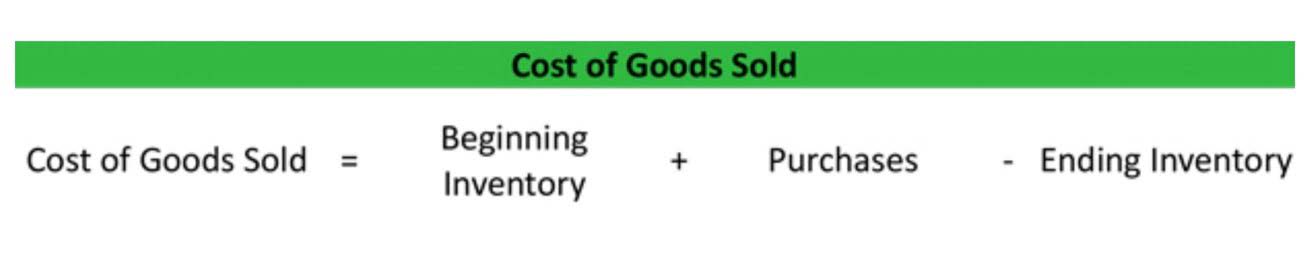

Ordering costs

Demand variability refers to the degree to which customer demand for a product fluctuates over time. In EOQ, higher demand variability poses a challenge as it introduces uncertainty. Let’s say you run a small clothing store that carries a popular baseball cap, and you sell 400 caps each year. It costs your company $3 per year to hold each hat in inventory, and the average order cost is $900. It is a measurement used in the field of Operations, Logistics, and Supply Management. In essence, EOQ is a tool used to determine the volume and frequency of orders required depreciation definition to satisfy a given level of demand while minimizing the cost per order.

Streamline, simplify, and systemize your inventory management

Notice that the quantity of 400 units with 6 annual orders and a combined ordering and holding cost of $120 is the most economical quantity to order. Other order quantities that result in more or less than six orders per year are not so economical. To address this, businesses may incorporate forecasting techniques specific to seasonal trends and employ safety stock strategies. By doing so, they can ensure adequate inventory during peak seasons, minimizing the risk of stockouts and optimizing customer satisfaction. This proactive approach ensures that the EOQ model remains accurate and aligned with the current realities of the business.

Regular monitoring, ideally conducted at regular intervals or in response to significant changes,. Businesses across diverse sectors can benefit from implementing EOQ strategies to enhance inventory efficiency and cost-effectiveness. Whether in manufacturing, retail, or distribution, EOQ provides a universal framework for efficient inventory management. The Economic Order Quantity (EOQ) is a valuable metric that provides insights into optimal inventory management. Therefore, implement data validation processes and regularly audit and clean the data to ensure accuracy.

Does EOQ Consider Seasonal Demand?

This ensures that the model accurately reflects the current state of the business. An increase in holding costs per unit per year leads to a decrease in EOQ and a decrease in holding costs per unit per year results in an increase in EOQ. An increase in demand leads to a higher EOQ, and a decrease in demand results in a lower EOQ. Higher demand requires larger order quantities to meet customer needs efficiently. Conversely, lower demand allows for smaller, more cost-effective orders.

We’ve also included tips and guidance to help you save time and avoid costly mistakes. An ERP/MRP system also facilitates the use of many other supply chain management techniques that are not so dependent on consistent demand. There are certain benefits the firms can reap by using the EOQ as a cost-scheduling and production-scheduling model. One most popular and common methods of calculating the quantity to be ordered are Economic Order Quantity (EOQ).

Establish strong relationships with reliable suppliers, communicate effectively, and implement contingency plans to address potential disruptions in the supply chain. Businesses can harness the power of technology to enhance EOQ management. Inventory management software and data analytics tools enable the collection and analysis of real-time data. An increase in ordering costs per order leads to a decrease in EOQ, and a decrease in ordering costs per order results in an increase in EOQ. It is a critical component of overseeing a company’s inventory-related activities such as ordering, storage, and utilization. That said, even the best supply chain is subject to unpredictable delays from time to time.

With a Dynamic EOQ, you calculate the EOQ with forecasted demand, tailoring order frequency to demand cycles. This keeps your inventory aligned with real demand—avoiding overstock during slow periods and stockouts when demand spikes. Calculating the cost of placing an order (Transaction Costs ) can be tricky because it’s more than a single expense. It includes all the fixed costs of each process involved in placing every order. In this example, we’re using a percentage of the item’s purchase price for simplicity. For accurate values, I recommend talking to your Finance Department, as they’ll have precise data on these cost factors.

These solutions are invaluable for businesses aiming to streamline inventory management and enhance overall efficiency. Including safety stock in EOQ calculations helps maintain service levels during unexpected demand spikes. By measuring days of supply, businesses can gauge how long current inventory will meet demand and adjust EOQ calculations accordingly. Businesses should monitor these costs closely and adjust their EOQ calculations to minimize costs and maintain optimal inventory levels. Accurate determination of setup costs is vital since it directly affects total inventory costs and the optimal order quantity. Using the EOQ formula allows businesses to find the right balance between ordering frequency and order size.